Health and safety and production - use of VR and AR

Virtual reality, assists plant managers and production directors by: leting the participant „prožít“ silné, nebo stresující situace – tak aby si remember mistakes and will never repeat them. Augmented reality guides users in technically tough situations, worker works faster and without a paper manual.

What will it bring you?

- Reducing the error rate of employees, v případě nestandardních situací – snížení škod.

- Strict compliance with directives, thanks to the experience in the simulator.

- Reduce the risk of damage skutečného stroje – savings for the company.

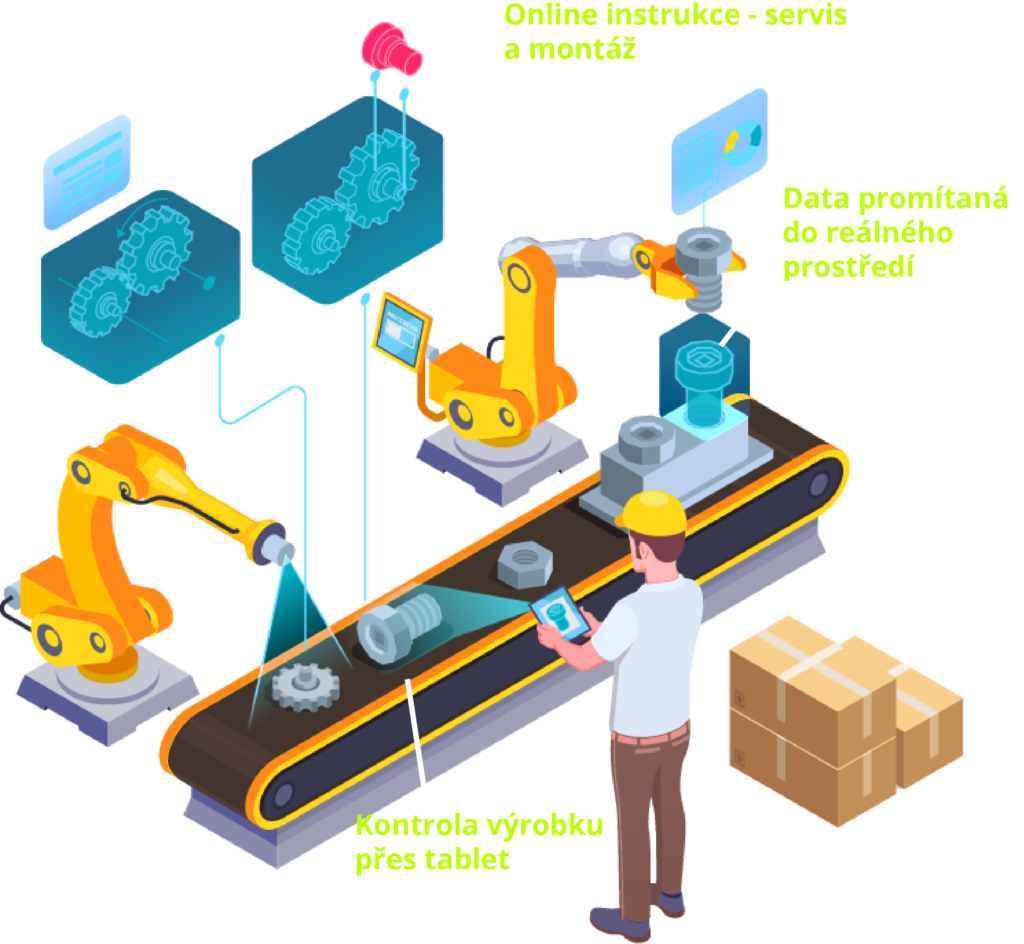

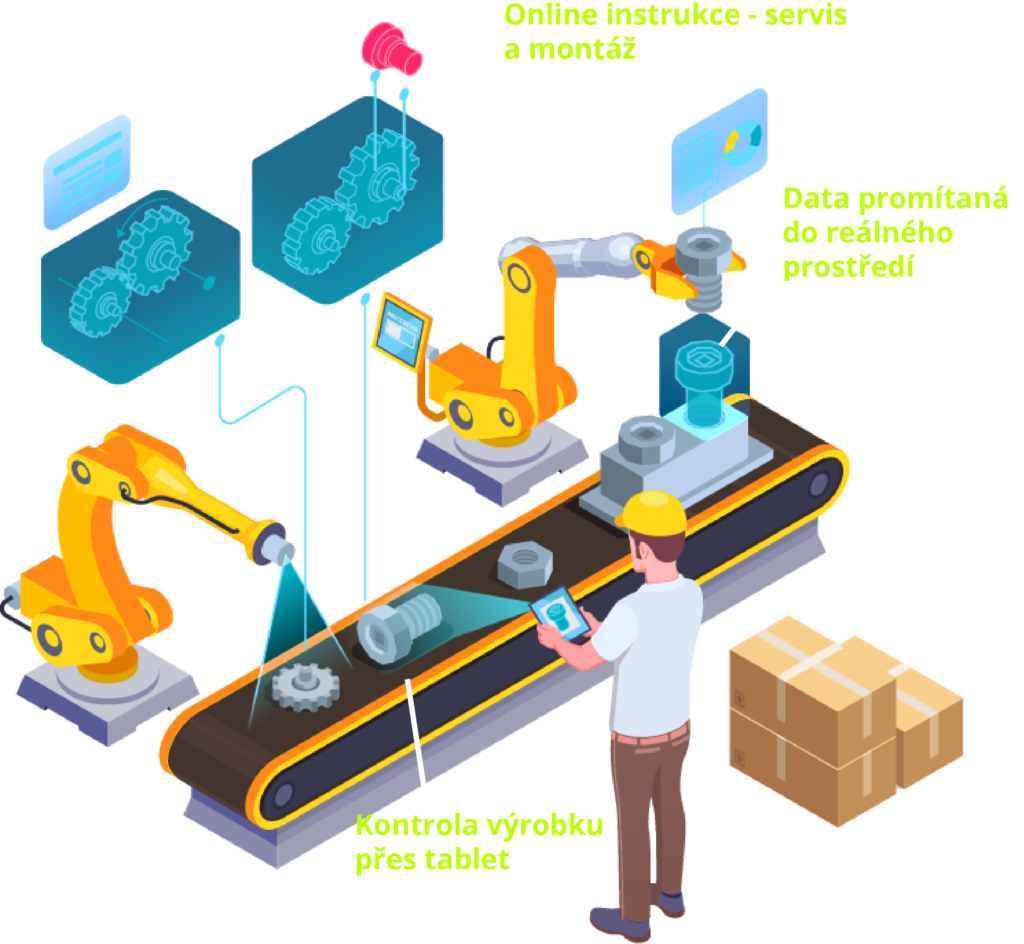

- Downtime is reduced, thanks to clear instructions using augmented reality. Increasing production efficiency.

- Participants have the opportunity to train dangerous operations in a safe environment without risk of injury.

- Acceleration of production due to augmented reality – uživatel nepoužívá papírový manuál, ale vše vidí přímo před očima.

- Even a less professional user can do highly professional work – úspora na lidech.

- The user can graduate in crisis decision training and the better to deal with non-standard situations

How does it work?

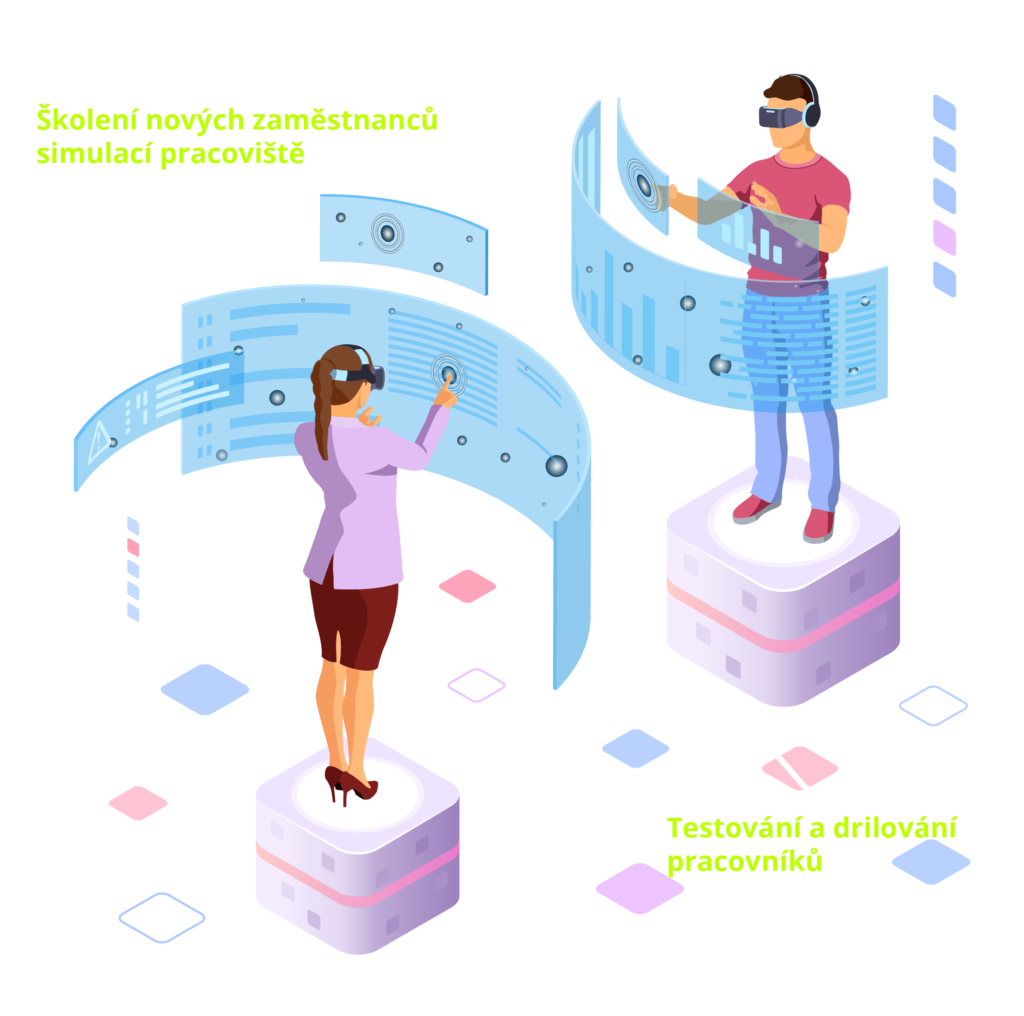

- The employee uses VR or AR glasses. This fully concentrates him on the work.

- He will meet working environment in 3D.

- System simulates the activities the user is to learn. Whether the machine operator, technical requirements, safety measures - in short, everything he will need for his work.

- VR tests the skills and knowledge of the employee, repeats the tasks until the student actually learns them.

- The simulation can create programmed actions that are difficult to try or train in reality.

- The AR, in turn, helps the worker process more professional tasks that he would not otherwise be able to do or could use using a paper manual or under supervision.

- Augmented reality also serves as remote assistance, in field service, or in highly professional activities.

- VR training is also suitable for already existing highly professional staff, to try out in the simulation new, unusual situations to deal with.

What can VR and AR be used for in production?

- Repeated drill and training. Virtual reality does not get tired.

- Virtual reality will ensure 100% concentration of the user.

- In VR we can simulate dangerous or unusual situations.

- Trainee does not need a trainer - everything he learns independently in the simulator,

- Te user will learn to operate real workplace, by using a simulator.

- User is evaluated and tested.

- The worker can train crisis situations and crisis thinking.

- Virtual reality is completely safe environment, where you can train any necessary activity.

Who already uses virtual and augmented reality?

Rolls Royce

Volkswagen

Linde

Is it worth it to you?

In order to be able to estimate whether VR and AR is right for you, you need to think about events such as:

Number of damage and repairs of machines, total service costs. Furthermore, the number of accidents at work, the length of downtime and non-use of machinery and equipment at work. Errors in crisis decision-making, when an employee misjudges a problem and leads to losses.

If you compare all of these items in terms of investing in technology such as virtual or augmented reality, you can make an informed decision about whether immersive technology will pay off.